I’m really enjoying the process of putting this van together. I might have saved some money by searching through the reusable building material stores for some of the parts. But I’ve just been buying everything new. Since the van is so tiny, the cost of covering the surfaces is also going to be minimal, even with nice materials.

As far as the layout for the cabinets, I simply put things where I thought they ought to go and took measurements. I needed the wall under the bed platform to extend out far enough to catch the edge of the countertop and still allow room for trim. I also needed to ensure enough room to fit my mini refrigerator under the counter

I built the cabinets with plywood, removed the water heater, and painted the insides.

I reconnected the water heater, then installed the countertop and sink.

I discovered that the bead board plywood I got from Home Depot was going to need extra framing in order for it to lay flat on the walls. It’s naturally a bit warped and won’t lay flat without additional fastening. So, I decided instead to use primed shiplap for the walls and ceiling. I’m only going to use the bead board for some contrasting accent walls. The ship lap is much sturdier. It does not flex much over the two foot span between studs.

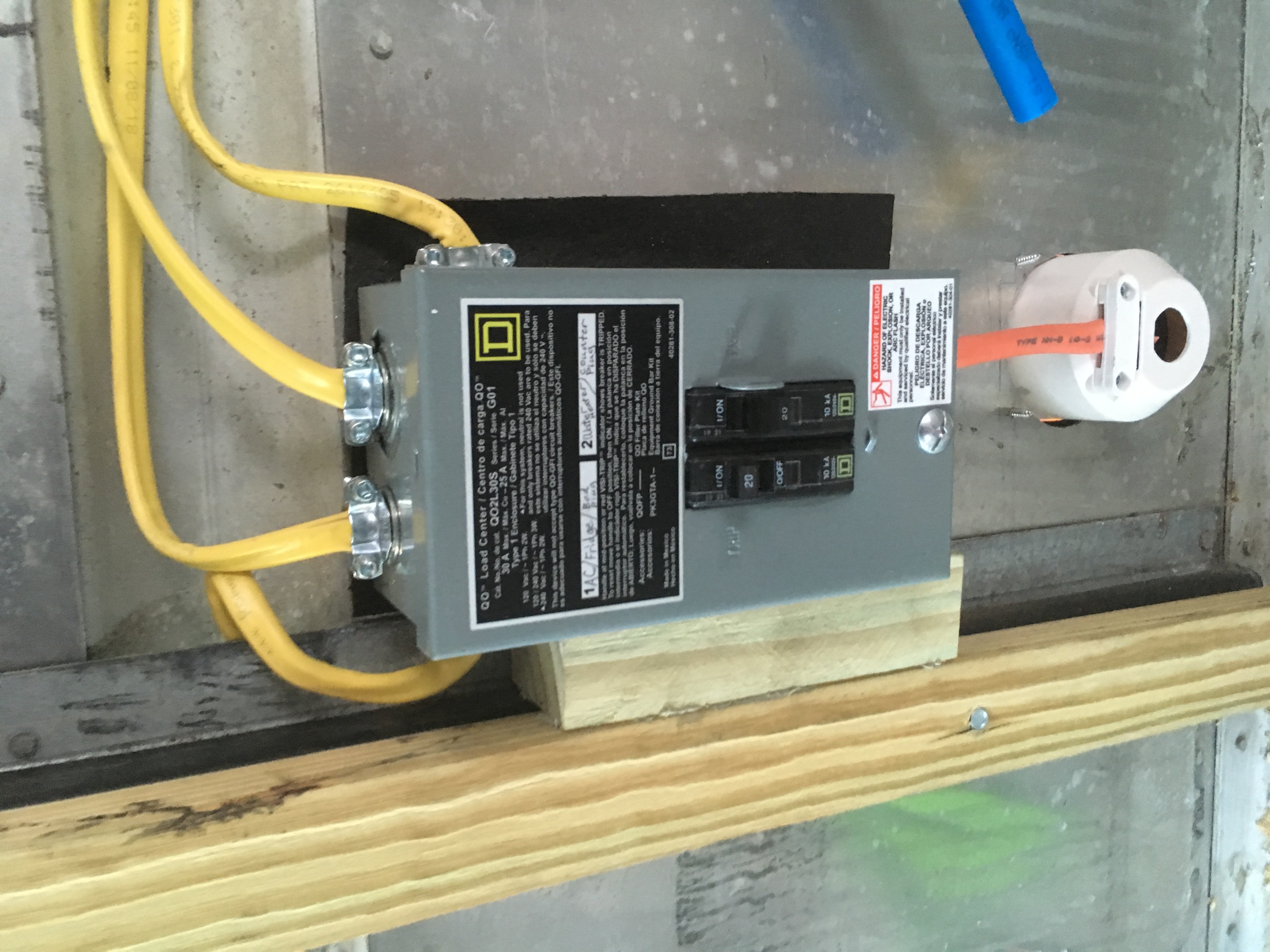

The kitchen area will eventually get a couple of upper cabinets. I think I will probably do more of the cabinet work next year. I also plan on installing an LED TV above and to the left of the sink. That is what the upper outlet is going to be for.

“I consider space to be a material. The articulation of space has come to take precedence over other concerns. I attempt to use sculptural form to make space distinct.”

~Richard Serra